Since the beginning, quality and customer service have been SAEMMPress main aim to operate on a more and more competitive and big market.

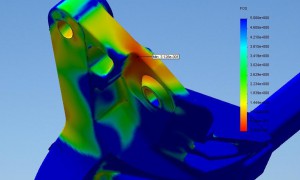

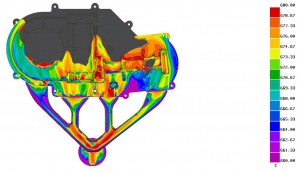

Quality, according to SAEMMPress, starts from the mould-design phase, goes through the choice of the best steels, the analysis and simulation of the filling flows and the proper positioning of the melting sprues. Considering quality from this very beginning means offering the highest efficiency and productivity to moulds life.

- A first check by the machine for each casting produced, which permits to find out in real time the main defects occurring during the melting process.

- A second check, on hourly basis, carried out with all necessary instruments to assure aesthetical, dimensional and functional conformity of the casting, together with a radiographic lab to test in real time its internal and structural integrity.

- A final check during the packaging phase to establish the final perfect product conformity.

Further, specific quality controls, besides the ones above, are implemented in the production flow, one for each kind of machining or finishing, on customer demand.

The quality system certification performs severe controls even on all material and service sub-suppliers, who have a direct effect on the product, especially on the choice of the most qualified refiners for the aluminium alloy supply.

SAEMMPress work constantly on the improvement of the environmental impact and, during the years, many environmentally friendly and energy saving policies have been adopted.

To reach this aim all production flows of new products are properly inspected; all ecological and chemical agents are attentively chosen together with all the machines to be according to environmental and safety regulations.

The company runs all necessary periodical controls according to laws and environment and safety regulations, continuously aiming at improvements.

Please contact us immediately to get all information about our production quality.